♦ With USB.flash and RS232C0M communication etc., many kinds of communication modes, can easily realize different data transmission and software update. With network interface, the system supports remote monitoring and transmission process of DNC file;

♦ open CNC platform,capable of customization system according to specific requirements;

♦ With complete self-diagnostic function, internal and external real-time display, it will show alarm if any exception;

♦ Support additional panel and external handheld box operation,it’s convenient to cutter aligner for customers;

♦ Macro-variable,programming of macro definition,enable to many kinds of logical relation.Support macro programming with parameter being used,more covenient to user;

♦ DXF + G code template function,switching the DXF file to G code for processing automatically;

♦ Teaching function: teaching+simple command programming, adopt table teaching mode, easy and direct viewing;

♦ Graphic simulation function: display processing program’s graph as well as tool’s moving track in actual movement, simulate cutting tool process with the machine not running to check whether the program we edit is correct;

♦ Multi-interface option: support multi-language interface display, auto alarm when breakdown. Abundant process information display of process time, numbers;

♦ Parameter tabulate: The I/O address can be set randomly when the right data is put in the address of configuration table;

♦ Built-in PLC core, functions extending flexible.

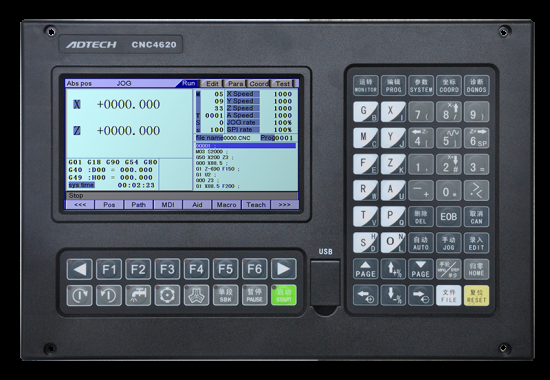

คอนโทรลเลอร์สำหรับเครื่องกลึง CNC รุ่น ADT-CNC9620 (2 แกน)

2 axis servo/step motor control; Good HMI design; Adopt embedded high speed processor and professional customized FPGA motion chip; Comprehensive function, support standard G code, DXF file and Macro function;

With large capacity storage, convenient to customers; Adopt high speed high accuracy algorithm to process to get good process effects