♦ U disk reading function, can be simulated as electronic hard drive to read edit and process datas, satisfying all kinds of large program’s workpiece processing;

♦ High process speed, can reach 20m/min;

♦ Complete, direct viewing of system running status, help user find problems in time, solve the problems easily;

♦ Support handheld box and extensional panel, convenient to operate;

♦ Support powerful B type macro resolving function, convenient for customers to develop their own motion control programs;

♦ DXF + G code template graph resolving;

♦ MST code external self define edit, easy to extend customers’fucntions;

♦ 3D graph simulation function;

♦ Power down save function, password protection function, screensaver function and so ๐n;

♦ Fully compatible with FANUC, mitsubishi G code and many kinds of CAM software( such as masterCAM, UG and so on.);

♦ Built-in PLC core, functions extending flexible.

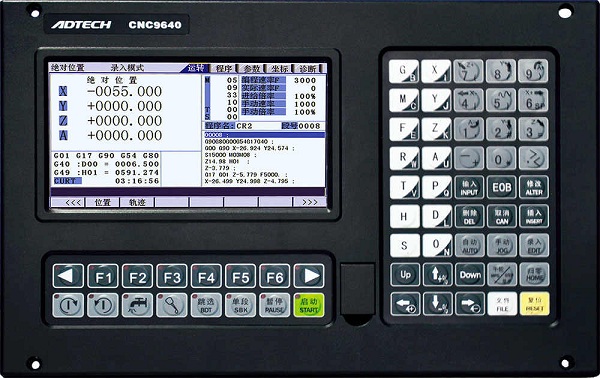

CONTROLLER CNC ADT-CNC9640 (4แกน)

10 inch big LCD screen; 4-8 axis servo/step motor control; Good HMI design;

Adopt embedded high speed processor and professional customized FPGA motion chip;

With open interface, flexible to extend; Comprehensive function, support standard G code, DXF file and Macro function;With large capacity storage, convenient to customers; Adopt high speed high accuracy algorithm to process to get good process effects; With high speed network data interchange interface.