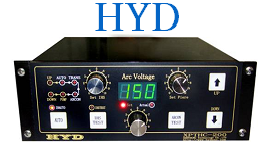

xpthc-200

Stand alone THC, works with almost any plasma cutter, sale over 2000 sets per year

No need software, all functions can be easily operated on THC(as picture showed)

1. New operation pane,

2. Support Dynamic pierce

3. Better anti-interference.

A. Auto Initial Height Sensing(IHS)

Torch Retaining Cap IHS and Proximity Switch IHS (NPN and PNP), Proximity Switch IHS is backup for Torch Retaining Cap IHS for cutting dirty/rusty workpiece, needing the Anti-Collision Fixture designed by HYD (optional ).

B.Torch Anti-Collision Function

We designed Touch-Up circuit for Anti-Collision Function. No matter it is on Auto Control Model or Manual Control Model, when torch head touches the workpiece, THC would automatically lift torch up to IHS height. So with XPTHC, even in Manual Control Model, user doesnt need to worry about torch head crashing.

C. Freeze Auto Height Control on Corner Signal

XPTHC can recognize Corner Signal from CNC and freeze Auto Control Model on receiving this signal, and we have a unique design to backup this function. We set 30V (adjustable) as Turning Point according to our years practice. When the Actual Arc Voltage is higher than Set Arc Voltage over 30V, THC Auto Control Mode freezes to avoid torch head diving, until it goes back to 30V range. This Over Voltage protection can avoid torch diving on voltage spikes (Corner Turning, Kerf Crossing) effectively.

D. Set Pierce Time

Set the Button (Set PIERE) to set Pierce Time.

E. Manual Operation

Many functions can be Manually operated on THC Operation Panel such as setting Auto/Manual, Up and Down, testing of IHS and Arc Start etc

F. Arc Voltage Divide

Isolation Voltage Divide detection, the Voltage Divide ratio is 100:1/50:1. And XPTHC-100 supports different HF plasma.